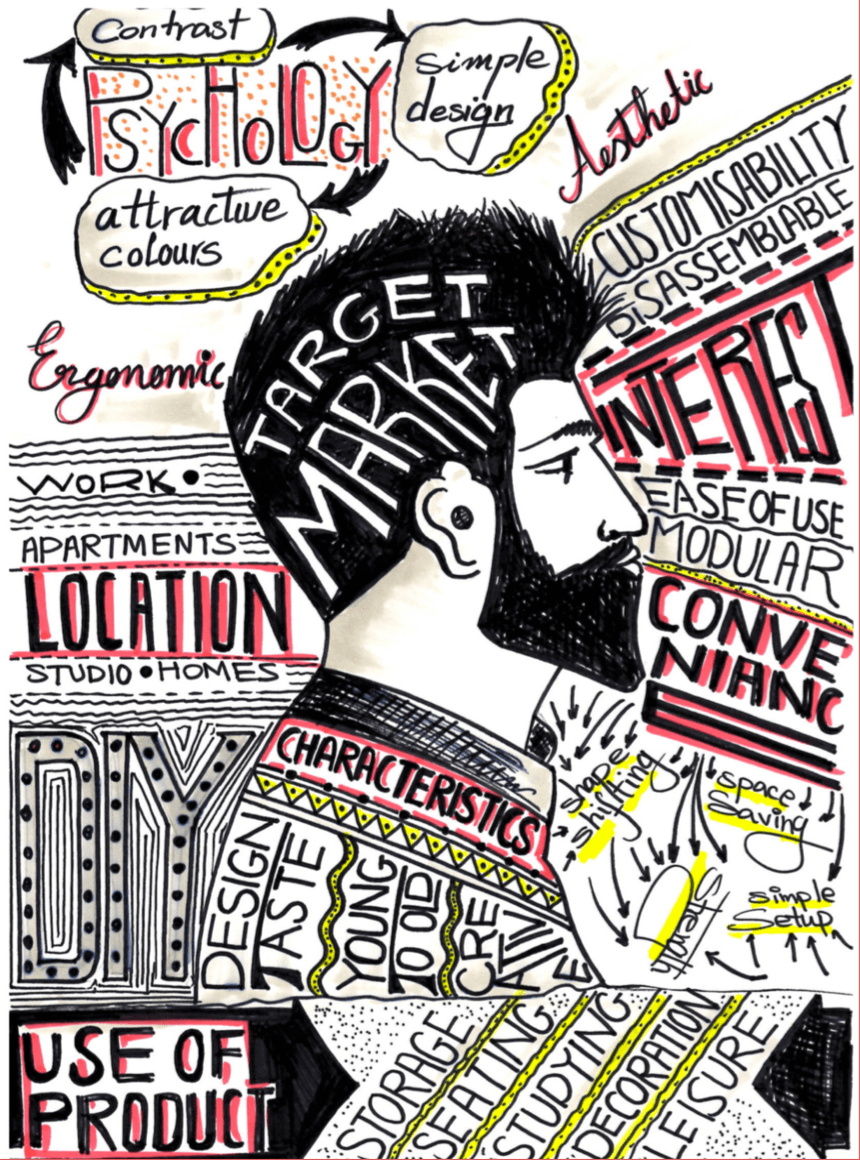

My motivation for this project is to apply both practical and theoretical skills and techniques which I have learnt in my previous year in design and technology and through independent research, to accomplish the task of creating a unique modular joinery system, as well as making good looking furniture which incorporates the joinery.

A goal for the end result of this project, would to run a website with different 3D joinery designs, where people can openly edit, download and share my designs, or be able to purchase furniture packs with joinery and wood.

Design is an important factor in this project, as it will complement the simplicity of the furniture. There is a lot more material savings with this process, and the ability to create items without any method of absolute joinery is the key for keeping the furniture unique. To have to ability to disassemble the furniture into pieces means cheaper shipping costs.

The aim of this project is to design and prototype a working joinery system where timber components can fit inside the joinery, with the use of male and female components.

The project should be able to simplify the processes of assembling traditional flat pack furniture, which often at times can be complex. There will be prototyping done with different 3D printed materials, including PLA plastic and metals.

Ideally, as an end product there would be a range of different furniture, varying in colours and materials, to demonstrate the variety which is enables in this design process.

I aim to make the project open source, and publish all documentation, files and ideas online to get feedback, or just simply share ideas and see what other can make.

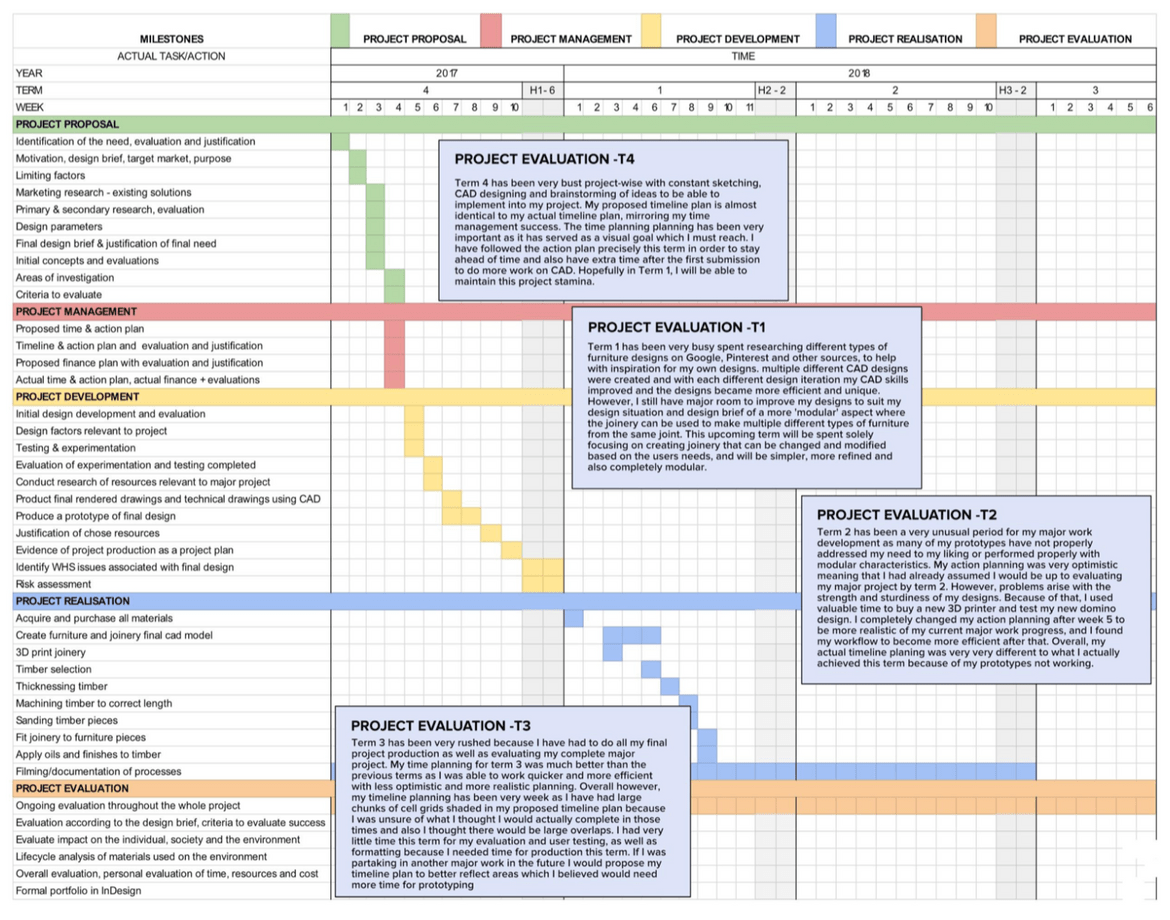

This is the timeline plan for my project, which I more or less strictly followed throughout the year.

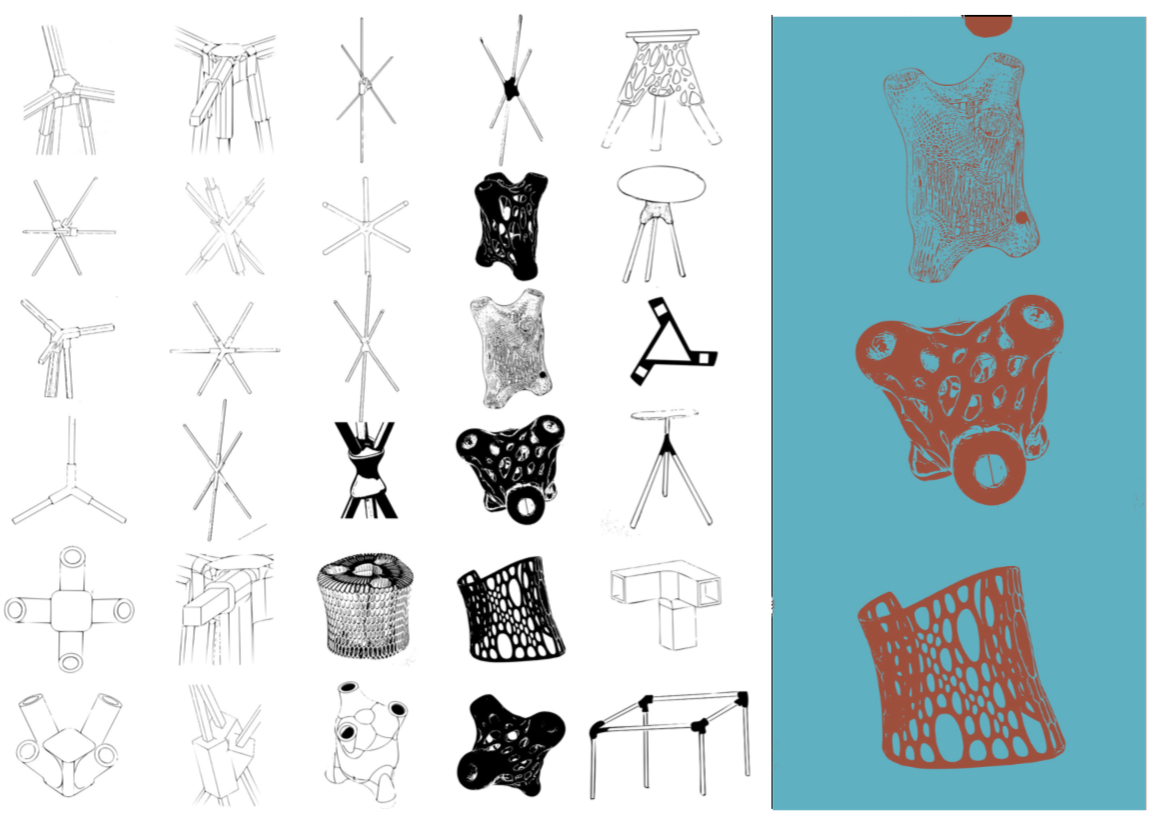

Here are some initial thumbnail sketches from the idea generation phase of my project.

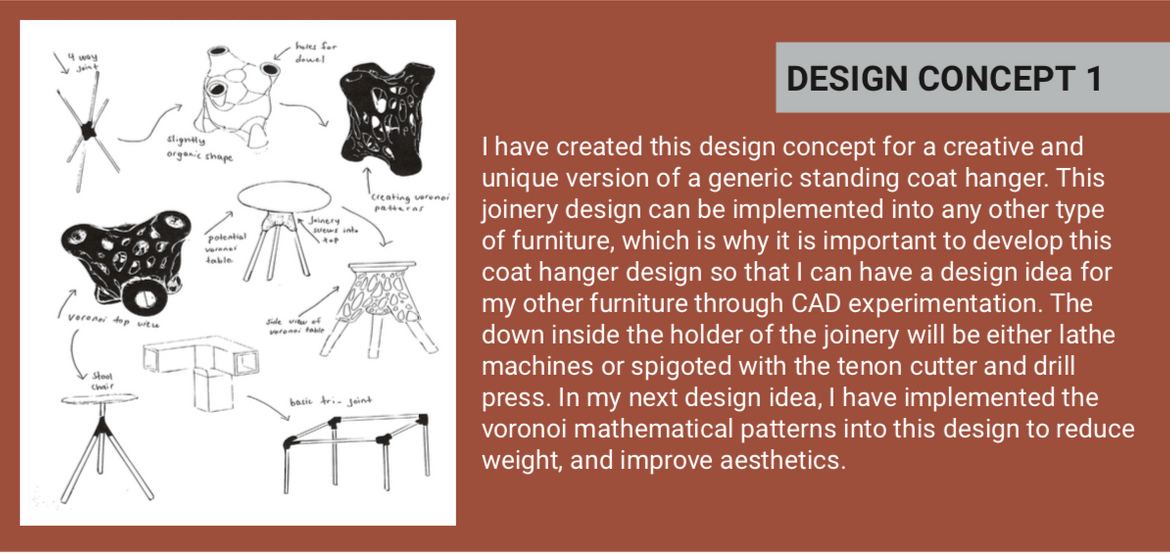

My first design concept.

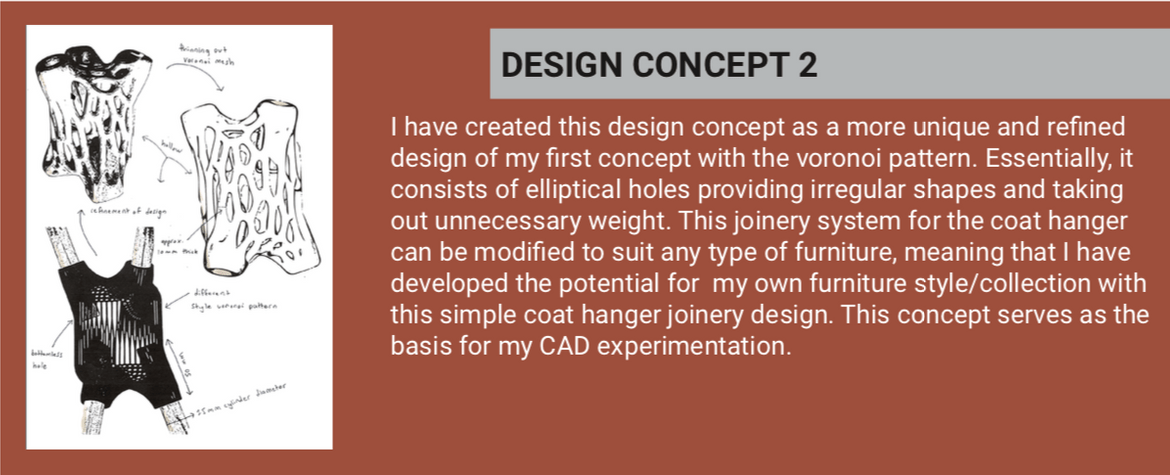

Concent two.

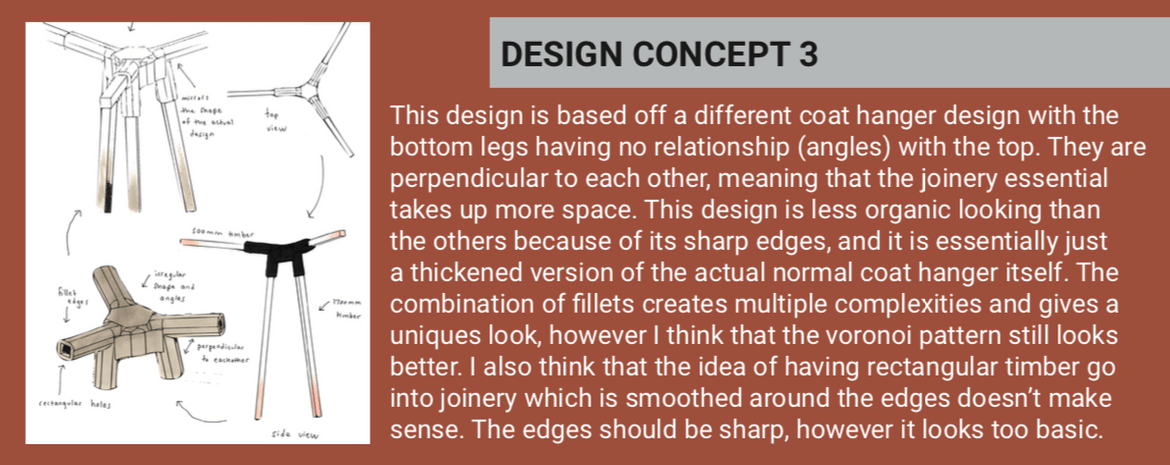

Concept three.

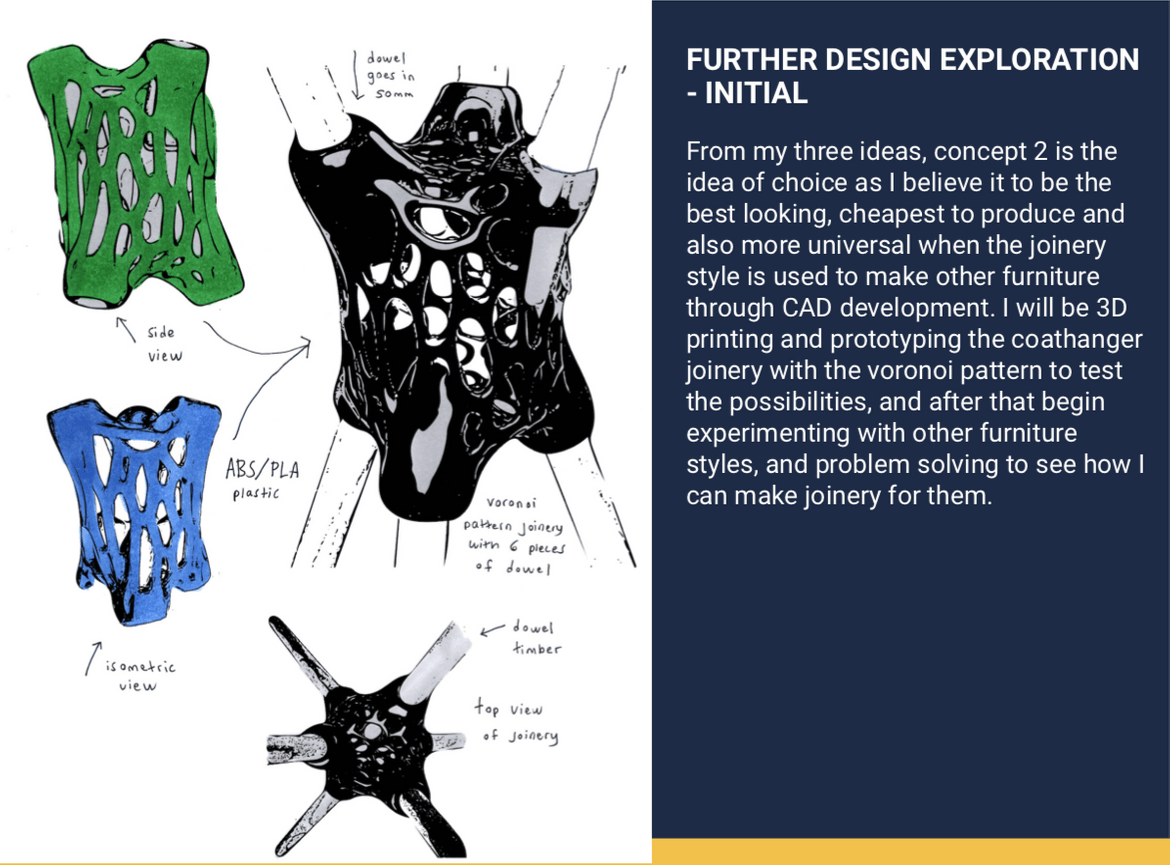

I thought I would explore this design further, but I ended up not even using it as a final design as I got some better ideas.

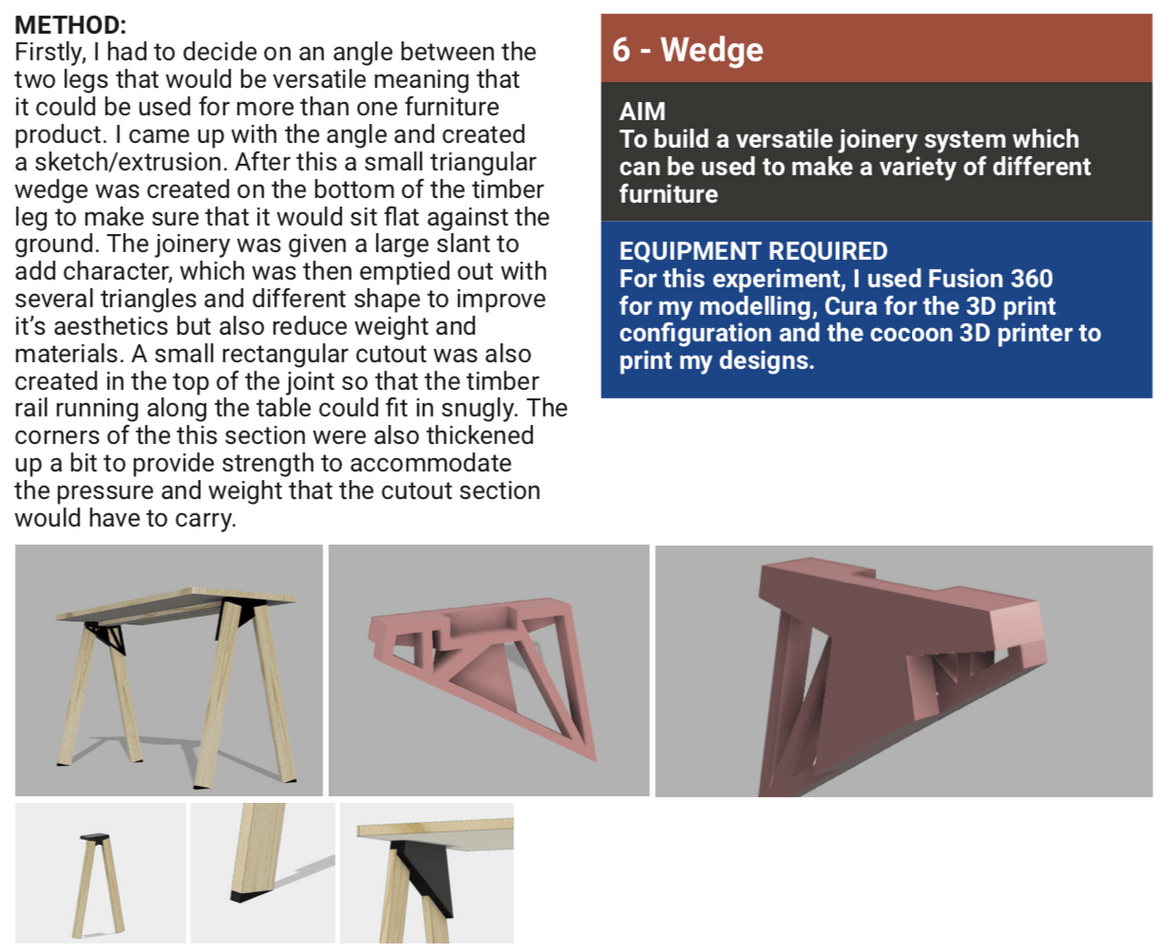

The first of many experiments I did to get to my final product.

Another notable experiment. I really liked the voronoi pattern and organic shapes at the time and wanted to try implement these into my design.

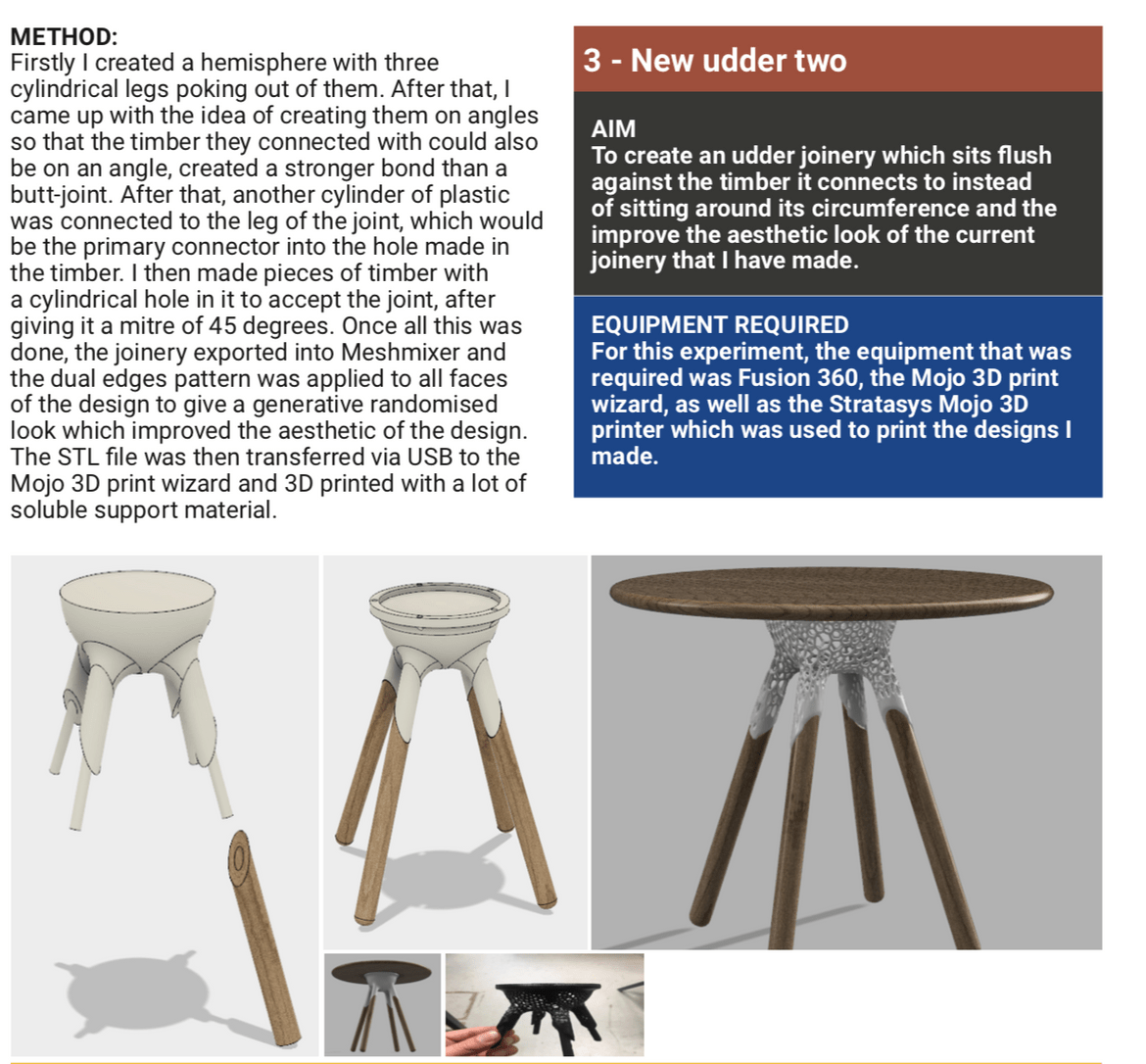

This idea/experiment was where I started to get on track and figure out my design idea. However it came with many, many problems of stability and structural integrity.

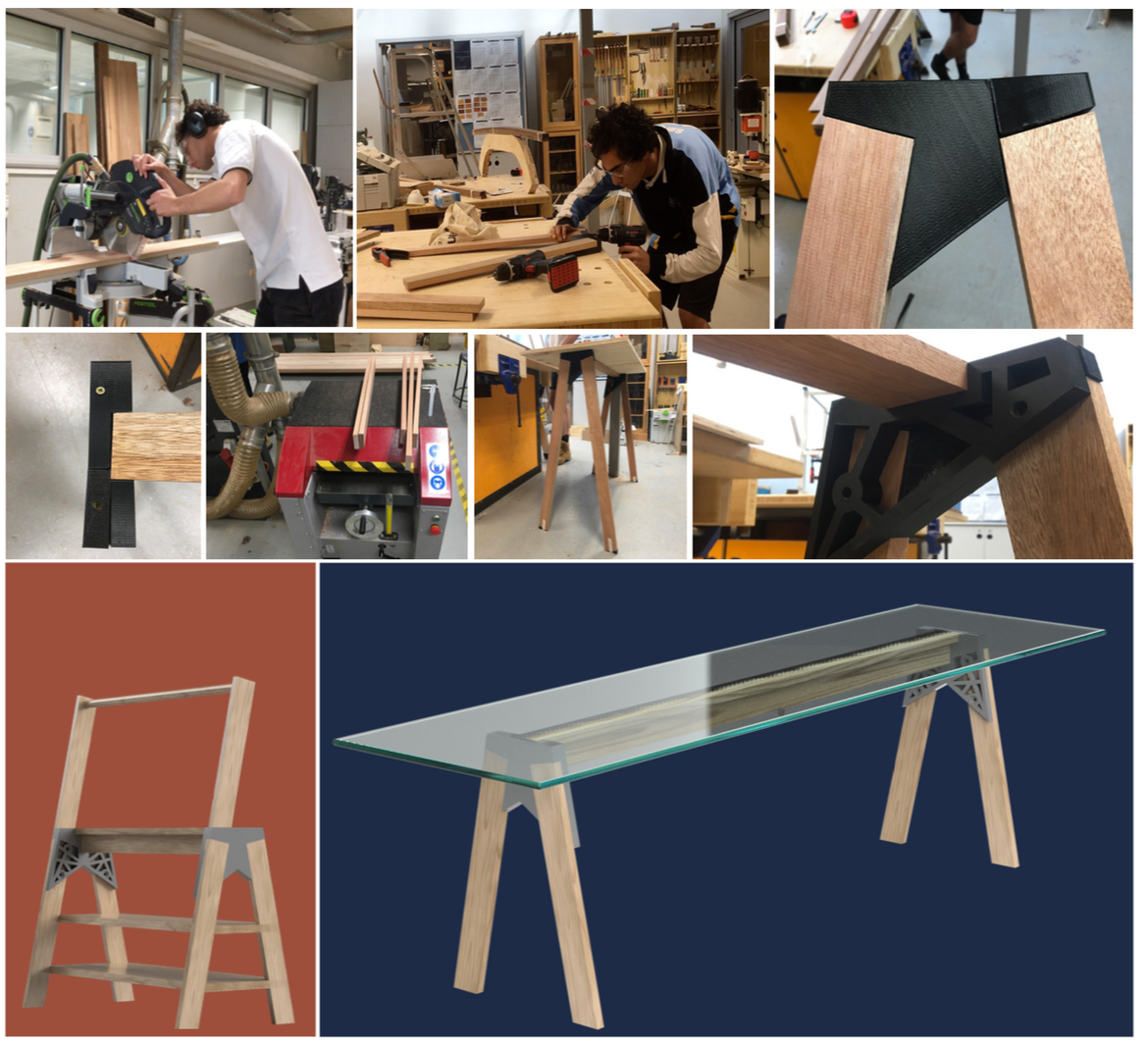

So I put these ideas to life and tried to build my first design prototype. I quickly ditched the idea of the plastic wedge under the timber legs to try keep it flat on the ground, opting to just cut the legs at an angle instead.

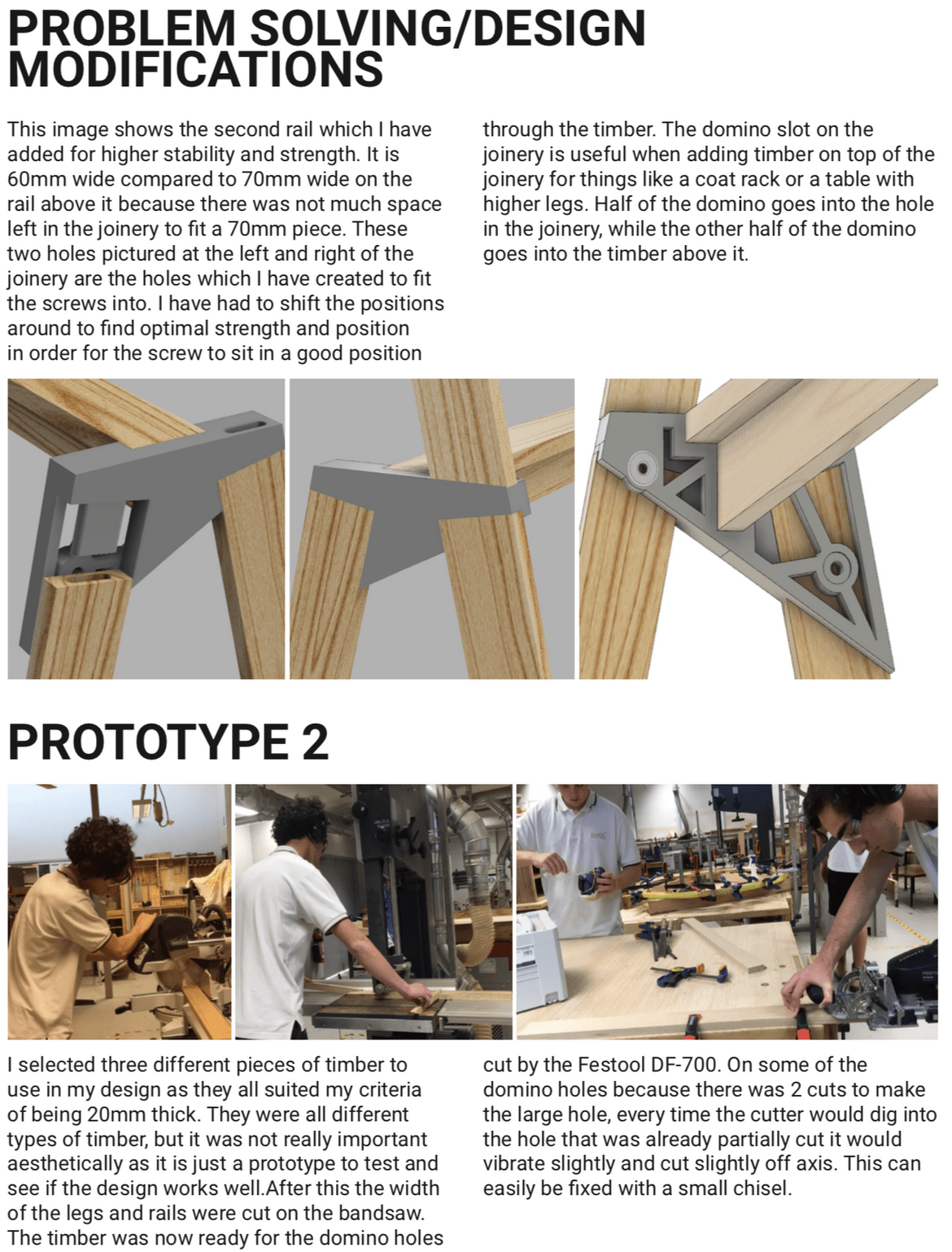

In the top you see the second prototype, which was pivotal because it allowed me to realise that the design needed strength and thus, thick domino joinery.

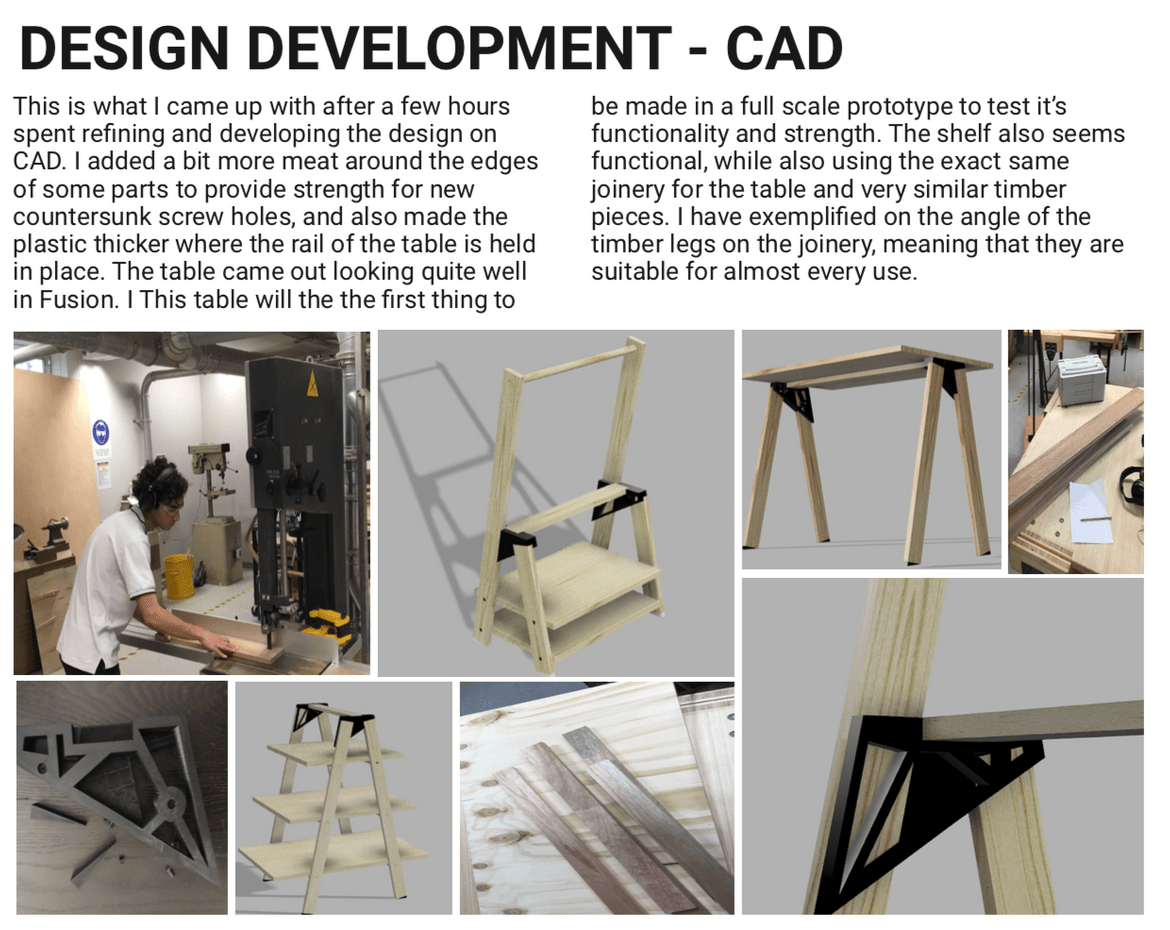

I designed my ideas on CAD too see if it would work, and it seemed like it should solve the stability problem alongside adding an extra rail through the middle of the table.

This one came out stronger than before, but still average in strength. I put it down to weak and flimsy timber, and one crucial aspest of the 3D printed joinery that had to be changed. Instead of the domino being built in to the joinery, it had to be seperate and sit in it’s own hole so it had strength and wouldn’t just snap easily.

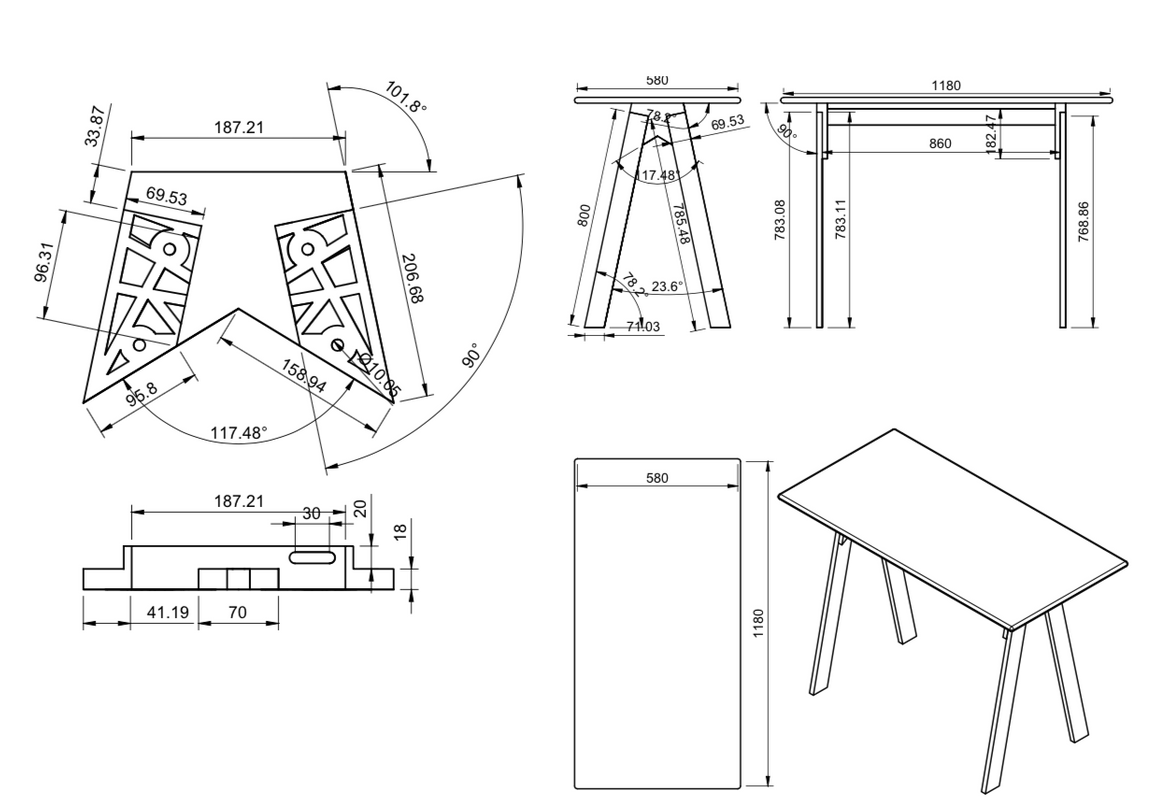

My technical drawings of my final joinery design and a table made from the joinery system.

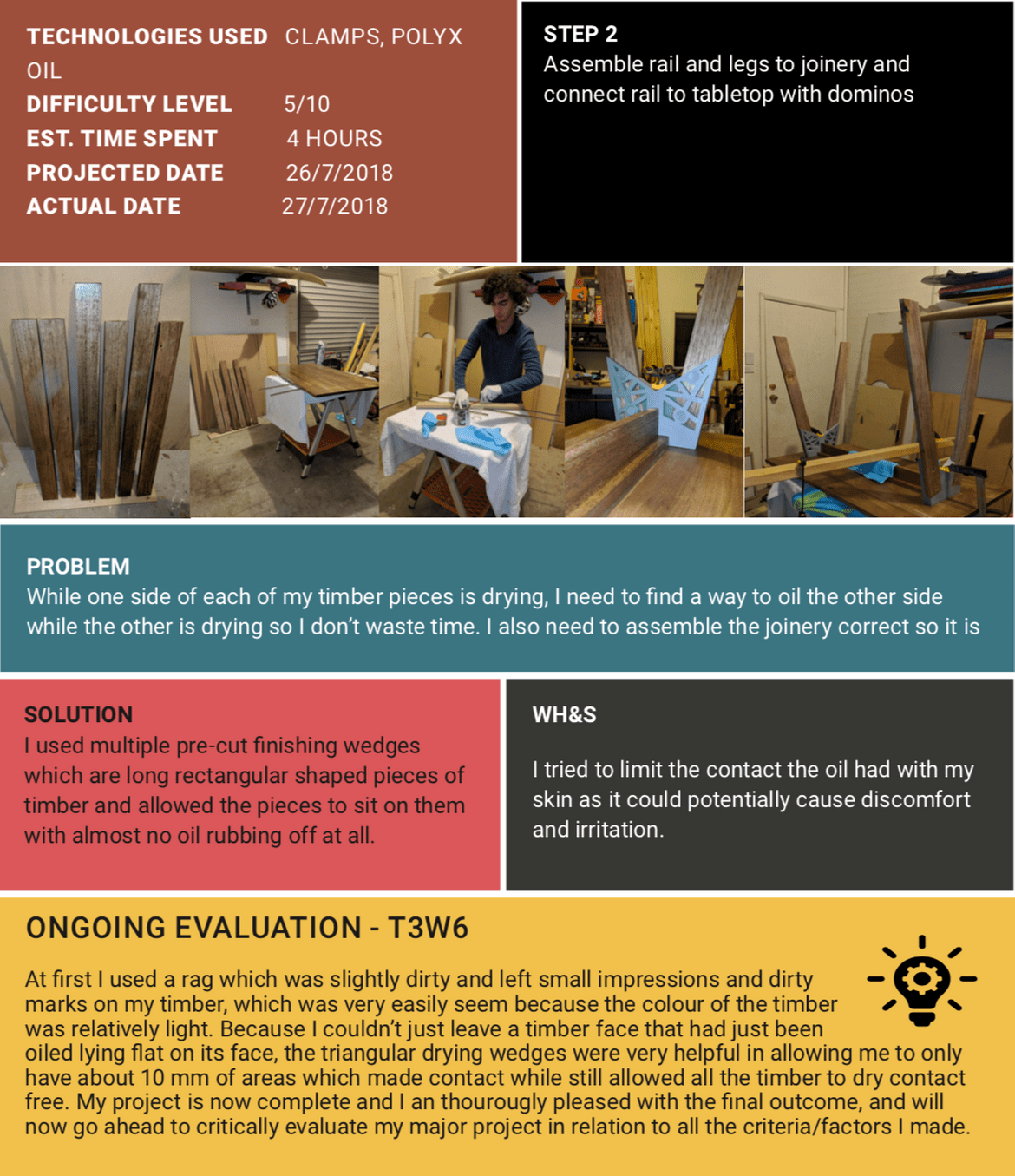

I face some problems in the final production phase of my project, however with some rational thought it always worked out in the end.

Here I am pictured oiling up the timber after assembly. With a bit of epoxy, stronger Tasmanian Oak timber and stronger domino joinery, I had eliminated 95% of the wobble, which I was happy with.

A render of the joinery system, and one of the products that it can be used for; a table.

The furniture trio. You can see this joinery is versatile, it’t not only limited to these tree pieces of furniture.

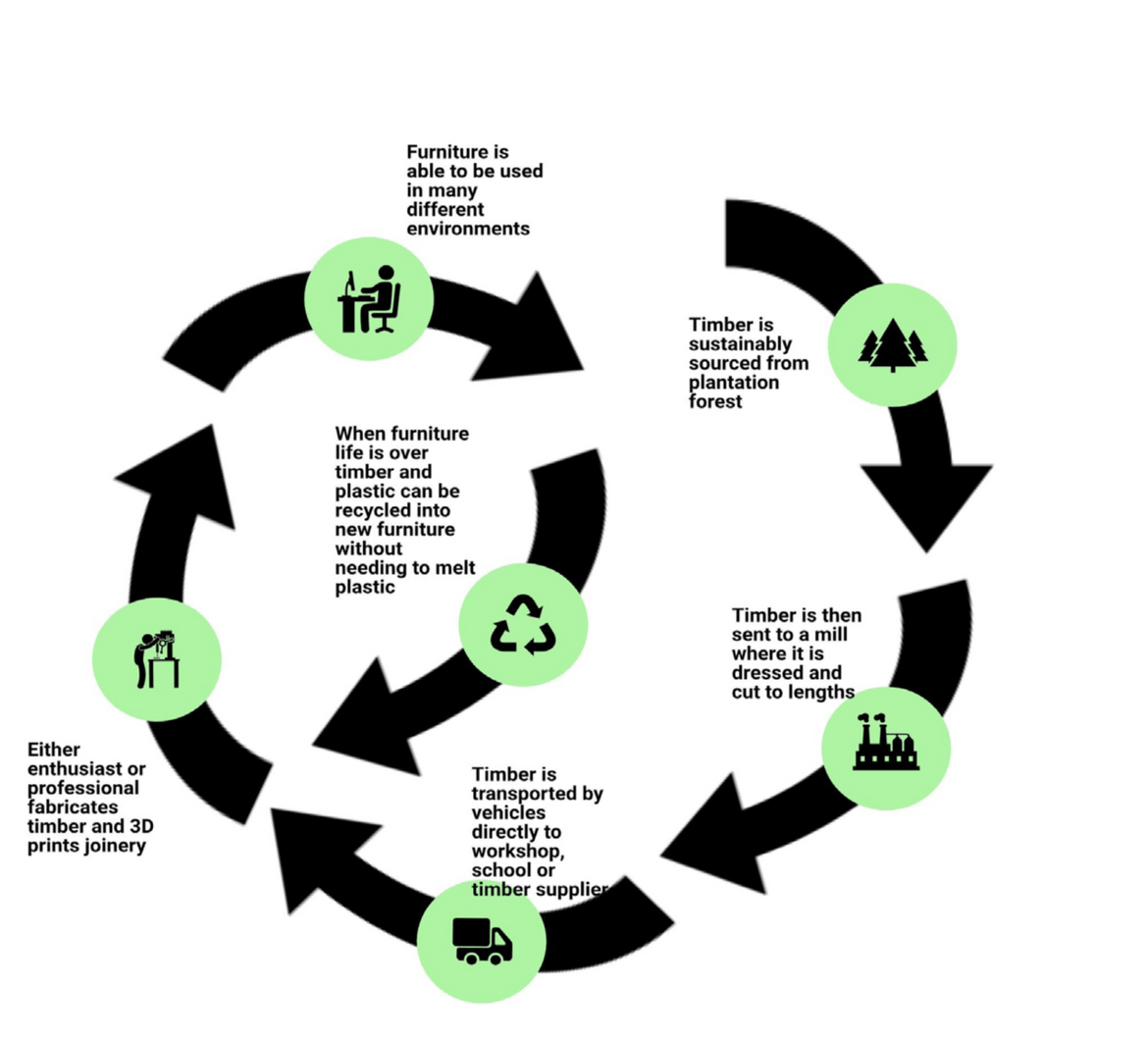

Here is the LCA, Life Cycle Analysis which I envisioned for my product from a real world business viewpoint.

Here I am standing with an initial prototype in my hand, and the final product next to me! Glad it was all over, one of the most stressful things I’ve ever made myself do thats for sure!

Another view.

Here is my process video, which gives a brief but nice description of my whole major project alongside some process videos.